Coltraco - Ultrasonic & Safety Instrumentation

- Fire Sprinklers

- Standard Coverage

- Commercial Extended Coverage

- Storage Sprinklers

- Residential Sprinklers

- Dry Barrel Sprinklers

- Special Sprinklers

- Sprinkler Accessories

- Spray Nozzles / Window Protection

- Wet Pipe Systems

- Dry Pipe Systems

- Deluge Systems

- Preaction Systems

- Model G Preaction Systems

- Single Interlocked – Pneumatic Release

- Single Interlocked – Electric Release

- Double Interlocked – Pneumatic/Pneumatic Release

- Double Interlocked – Electric/Pneumatic Release

- Double Interlocked – Electric/Pneu-lectric Release

- Components and Accessories (general)

- Accessories (Pneumatic Release)

- Accessories (Hydraulic Release)

- Accessories (Electric Release)

- Alarm Devices

- Special Valves and Trim

- Valves and Systems

- Foam Systems and Accessories

- Foam Systems

- Concentrate Control Valves and Trim

- Valve Trim for Premixed Foam Systems

- Release Trim Packages

- Foam Concentrates

- Accessories, Foam Concentrates

- Proportioning Devices

- Discharge Devices

- Bladder Tanks

- Double Wall (SAFE) Atmospheric Storage Tanks

- Single Wall Atmospheric Storage Tanks

- Atmospheric Storage Tank Optional Equipment

- FoamPak Foam Pump Skid, 60Hz, Single and Dual

- FoamPak Foam Pump Skid, 50Hz, Single and Dual

- FoamPak Accessories

- Miscellaneous

- Portable Fire Equipment

- Fire Detection Systems

- Addressable Fire Alarm Systems

- Vigilant MX1 Addressable Panels

- MX1 Addressable Fire Panels

- AS1668 Controls and Gas Controls for MX1

- Addressable Detection & 850EMTK Programmer

- Addressable Modules and Field Devices

- Graphic Monitoring Software - XLG Client Server

- Vigilant Empty Cabinets & Battery Boxes

- IP Interface Networking

- MX Hazardous Detectors / Devices

- Documentation and Manuals

- Vigilant MX4428 & F4000 Addressable Systems

- ASE Parts

- Vigilant MX1 Addressable Panels

- Emergency Warning Systems

- QE20 EWCIE and QE90 EWIS

- Occupant Warning Systems

- Grade 2 and 3 EWS T-Gen2 AS4428.16 Approved

- Grade 2 and 3 EWS T-Gen2 AS4428.16 Approved

- Older Style OWS Amplifiers

- Evacuation Speakers

- WIP Phones & WIP Cabinets

- VOX Speech Intelligibility Test Kits

- Miscellaneous Tools & Items

- Conventional Fire Alarm Systems

- Maintenance Testing Equipment

- Flame Detection

- Ancillaries

- Cabinets

- Speaker Testing Equipment

- Miscellaneous Spare Parts

- Coltraco - Ultrasonic & Safety Instrumentation

- Photoelectric Smoke Alarms Stand Alone – Battery Powered

- OSID Emitters & Imagers

- Anti-Tamper Device

- FBA

- Gas Panel Signage

- Looms and Ribbon Cables

- Power Supplies

- Addressable Fire Alarm Systems

- VESDA ASD Detectors

- VESDA & FAAST FLEX Detectors

- VESDA Life Expectancy 2015

- Xtralis AS1851.2012 Maintenance

- VESDA LCD Programmer & High Level Interfaces

- VESDA-E Backward Compatibility Table - Firmware Versions

- Filters & Spare Parts

- VESDA Software

- Pipe and Fittings

- Automatic Air Purging System

- 19" Rackmount Configurations

- Gas Detection for VESDA

- VESDA Remote Displays

- Power Supplies

- VSM4 Configuration & Monitoring Software

- VESDA Documentation & Manuals

- VESDA Life Expectancy 2015

- Xtralis AS1851.2012 Maintenance

- VESDA-E Backward Compatibility Table – Firmware Versions

- VESDA Product Manuals & Data Sheets

- VESDA Technical Tips

- VESDA Maintenance & Troubleshooting

- VESDA Design & Commissioning

- VESDA Industry Documents

- VESDA Aspirated Smoke Detection for Impulse (Jet) Fans in Carparks

- VESDA Refrigerated Cold Storage Facilities - Design Guide & Information

- VESDA Case Studies

- VESDA Movies

- Smoke Bombs & Smoke Pens

- FAAST FLEX Documentation & Manuals

- Suppression Systems

- Hangers & Fasteners

- Exit & Emergency Lighting

- Foam Products

- Electrical Products

- Steel Pipe & Fittings

- Alarm Devices & Monitoring

- Signage & Blazons

- Tools & Accessories

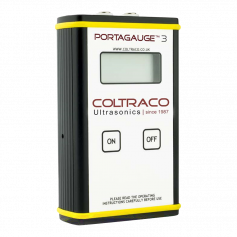

View larger

View larger Portalevel® MAX Ultrasonic Liquid Level Indicator Test Kit

PL-MAX

FlameStop are the exclusive New Zealand distributor for the Coltraco Portalevel® MAX

- DESIGNED to inspect the content of Fire Suppression System Cylinders of CO2, FM-200™, NOVEC 1230, FE-13, FE-25, NAF S III, CEA410, Halons and a range of other extinguishing agents.

- UNPARALLELED new display and operation methods Portalevel® MAX will help to make your business more efficient and enhance the safety practices of your company and customers.

- IDEAL tool to replace weighing and radioactive devices as a typical method of testing.

- QUICK, accurate and efficient method of inspecting cylinder content.

Availability date:

FlameStop are the exclusive New Zealand distributor for the Coltraco Portalevel® MAX

- DESIGNED to inspect the content of Fire Suppression System Cylinders of CO2, FM-200™, NOVEC 1230, FE-13, FE-25, NAF S III, CEA410, Halons and a range of other extinguishing agents.

- UNPARALLELED new display and operation methods Portalevel® MAX will help to make your business more efficient and enhance the safety practices of your company and customers.

- IDEAL tool to replace weighing and radioactive devices as a typical method of testing.

- QUICK, accurate and efficient method of inspecting cylinder content.

Downloads

OTHER

Product Information

FlameStop are the exclusive New Zealand distributor for the Coltraco Portalevel® MAX

- DESIGNED to inspect the content of Fire Suppression System Cylinders of CO2, FM-200™, NOVEC 1230, FE-13, FE-25, NAF S III, CEA410, Halons and a range of other extinguishing agents.

- UNPARALLELED new display and operation methods Portalevel® MAX will help to make your business more efficient and enhance the safety practices of your company and customers.

- IDEAL tool to replace weighing and radioactive devices as a typical method of testing.

- QUICK, accurate and efficient method of inspecting cylinder content.

Approvals

- Assembled under IPC-A-610 American national standards, institute protocols and full ESD electrostatic discharge protocols; finished with lead-free

- Rohs compliant Tin/Copper Sn100C patented solder

- Environmental metal enclosure rated to iP65

- UL Approved and Certified manufactured Circuit boards to UL specifications

- RinA Classification Society Approved

- UK Government CAGE Code KD983

- P/n: 2290334-COMX

- UL Approval Certificate number: 20140310-E455148

How Does It Work?

the Portalevel® MAX has been speci cally designed to be as easy, simple and definitive for a user to operate as possible. Simple touch buttons now operate the controls and a new digital screen provides clear and definitive results to the user. The 7 steps below outline the simple testing process. further technical support is available to all users for the life-time of the equipment if required.

- Attach the sensor to the main Portalevel® MAX, switch the unit on and ensure the “battery Low” indication is not showing.

- Depending on the condition of the cylinder, some couplant may need to be applied to the side of the cylinder, this could be in the form of Water spray, Ultrasonic Gel or an Oil & Water mix de-pending on what is easily accessible. this is not always essential and they all accomplish the required results.

- Place the senor towards the top of the cylinder and engage the “CAL” feature. This will set the unit to that particular cylinder, catering for the material thickness, paint or surface covering.

- When engaging the “CAL” feature, the bar Graph on the screen will extend all the way to the right and the numbers will read high values.

- The user should then move the sensor down the cylinder in small steps, making sure not to drag the sensor down the cylinder face.

- When the sensor passes the level mark, the numbers will drop dramatically and the bar graph will reduce all the way to the left. It is this change in display readings which identi es the difference between Air (above Level) and Liquid (below Level) in a cylinder.

- Through moving the sensor up in smaller steps, one can accurately pinpoint the exact liquid level location.

Contents

Portalevel® MAX comes in a ready-to-go package complete with all items required for liquid level indication:

- Hard wearing carrying case

- Ultrasonic Gel

- Standard Dry Sensor

- Cable and applicator

- Calibration Certificate valid for a year at a time

- Operating instructions

- Main electronic unit

- WARRANTY: Our manufactured instrumentation has a 3 year warranty; sensors have a 1 year warranty.